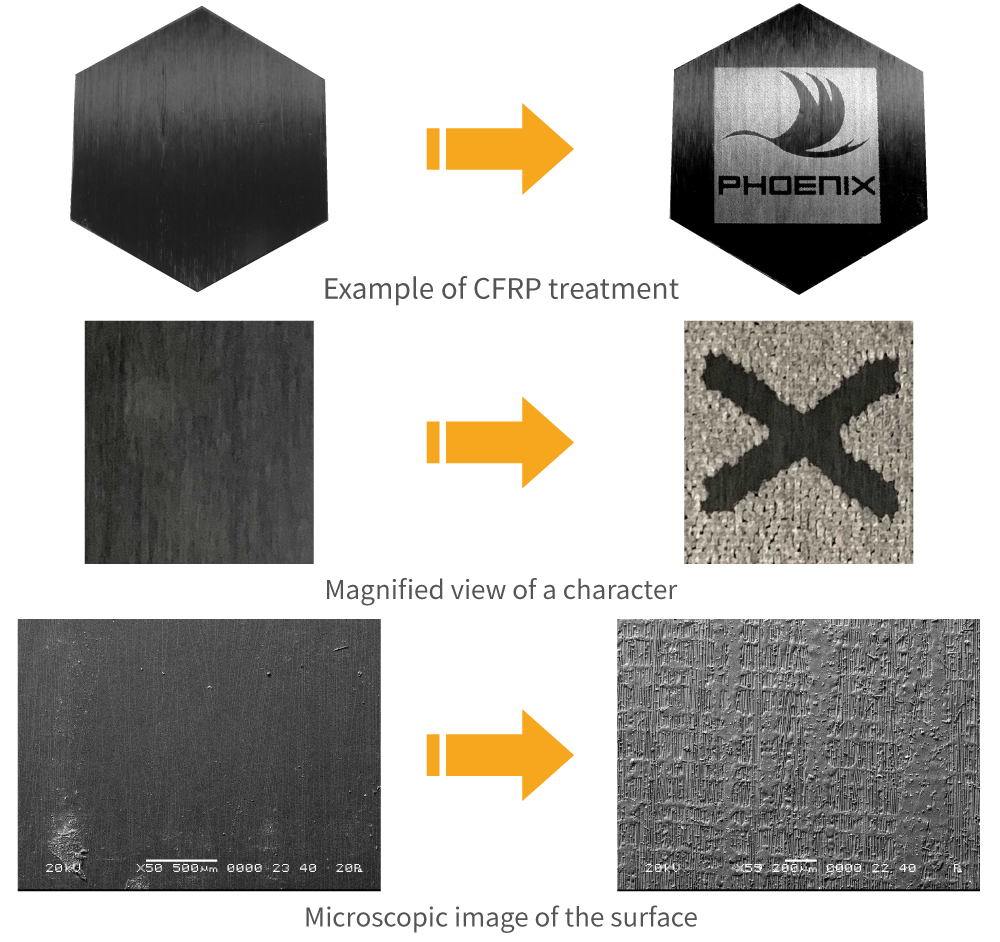

CFRP surface treatment unit

Laser Ablaser

Easily removes epoxy resin as well

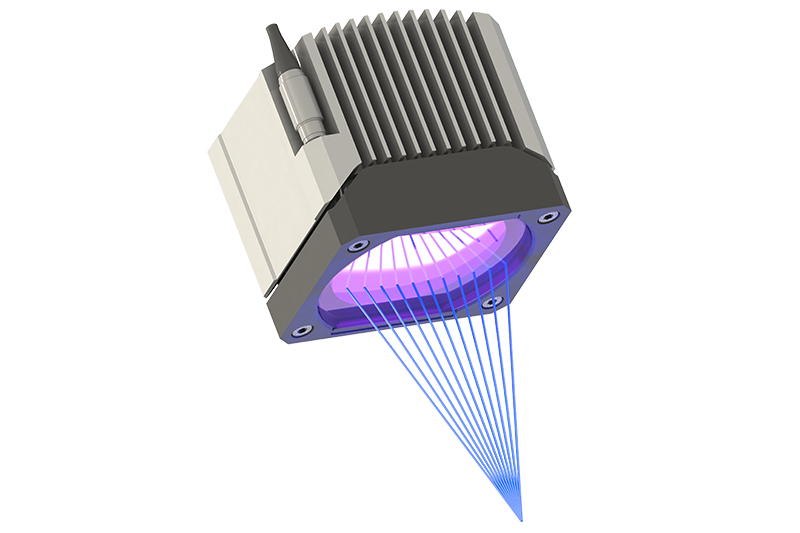

Multi-lamp light source unit

using semiconductor lasers

Overview of Laser Ablaser

Laser Ablaser is equipped with multiple semiconductor lasers using PHOENIX Electric’s proprietary optical technology.

The CFRP surface treatment unit is exceptionally reliable and can be used in a clean environment, eliminating the need for large environmental pollution control equipment.

Laser Ablaser solves the problems of conventional systems and delivers automated, unmanned operation.

It also helps reduce the initial and treatment costs.

We are committed to developing higher output and functionality to achieve surface treatment systems for materials other than CFRP.

Features of Laser Ablaser,

a CFRP surface treatment unit manufactured by PHOENIX Electric

Laser Ablaser offers the following versatile advantages.

- High-speed treatment

– High-speed laser treatment exceeding 1,000 mm per second. - Reliability for high bonding strength

– The surface treatment eliminates unevenness caused by sand blasting. - High accuracy

– Surface and line irradiation ensures high-speed, high-accuracy treatment. - Cost reduction

– Laser Ablaser is significantly cheaper than other systems that use carbon dioxide laser, etc.

Laser Ablaser has been verified to be compatible with various driving systems.

Because Laser Ablaser does not require ventilation or drainage equipment, it enables automated, unmanned operation.

Example of specifications (a 31-lamp unit)

| Irradiation light energy | 37 W |

|---|---|

| Surface treatment width | 6 mm |

| Scanning speed | 1,200 mm/sec |

| Scanning method | Vector scanning |

| Treatment capacity | 3 min/m2 |

| LD drive pulse width | 50 nsec or more (optimized depending on the material whose surface is to be modified) |

| LD cooling method | Air-cooled |